TTS-800/60 STANDARD Industrial Band Frame Sawing Machine

6 July 2019

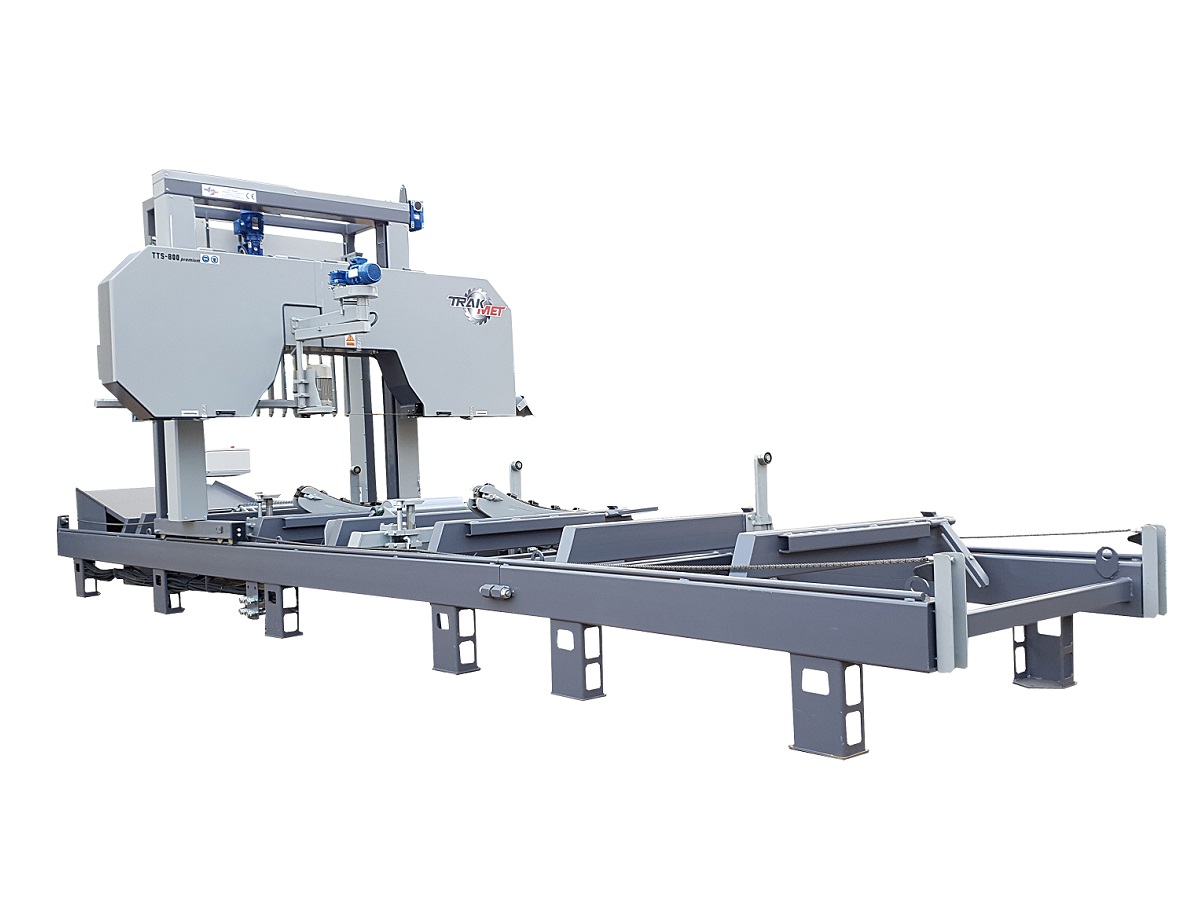

TTS-800 PREMIUM Wide-Band Frame Sawing Machine

7 July 2019

This is a modern machine featuring a very high capacity and accuracy of cutting. One of its most important assets is the use of guiding wheels with a diameter of 800 mm as the carrier of the cutting band with a width of 60 mm. This type of band requires no rolling, and the process of saw preparation prior to cutting is carried out using conventional sharpening equipment.

Such a solution combined with the innovative design of the machine allows the achievement of sawing performance and quality similar to wide-band frame sawing machines with a 100 mm wide band. However, operating costs, such as electricity consumption and the price of the band, are incomparably lower.

The band frame sawing machine is equipped with many innovative solutions, significantly increasing the performance and accuracy of cutting, such as:

- 800 mm guiding wheels with the PK-type belt for maximum service life of the blade.

- 60 mm wide cutting blade with a 2 mm Stellite blade and the 25 mm tooth pitch, increasing sawing speed by 30%, operating intervals between saw change up to 3 hours.

- double-sided, emulsion-cooled guiding slides that reduce friction during the sawing process, which has a direct impact on lower energy consumption, higher cutting speeds and noise reduction.

- double-sided chain-controlled longitudinal drive of the cutting head.

- precise and fast chain positioning of the cutting head 30 mm/s.

- extended efficient hydraulic system for the unobstructed manoeuvring of large logs up to 5 tonnes, possibility of changing hydraulic tools.

- machine track substructure made of solid hollow profiles (200 mm x 120 mm x 6 mm) supported on both sides.

TECHNICAL DATA:

- weight - 3900 kg

- main motor power – 22 KW (optionally18,5 -30 KW)

- power demand – 26-37 KW (for full option)

- supply voltage - 380V, 50Hz

- up-down vertical chain movement 30mm/s

- double-sided chain-controlled longitudinal feed of the cutting head – variable inverter 0-40 linear metres/min

- manual feed of tension slides - electric

- 800 mm blade guiding wheels

- standard substructure length – 6 m (sawing length 4.8 m)

- electric stationary control panel

- cooling emulsion solenoid valve

- ISP-10 electronic cutting thickness control unit

- cutting head clearance – 420/1150 mm

- kerf thickness - 1,5-2,2

- hydraulic system:

clamp x 1, angle locking elements x 4, log loading 3 m wide x 1, levelling with forward and backward log feed x 1, levelling without drive x 1, chain rotating device x 1 - sawing machine substructure made of a hollow profile 200mm x 120mm x 6mm

- frame-based design of the cutting head, supported on both sides

- moderate output

- stellite blade – 5600 x 60 x 1.1, pitch 25 mm (output 23-28 m3/10h)

- blade – 5600 x 60 x 1.1, pitch 22 mm (output 17-22 m3/10h )

OVERALL DIMENSIONS:

- length - 6000 mm

- width - 2900 mm

- height - 3050 mm

Trak-Met based in Biskupiec, Poland, is currently the first and only manufacturer in the world – since 2012 – with serial production of band frame sawing machines using the cutting process with the 60 mm wide standard sawing band or the Stellite blade and the 25 mm tooth pitch. In terms of the process, the quality and performance while sawing with the wide-band frame sawing machine is achieved, and the lowest operation-to-performance ratio is maintained.

OPTIONAL EQUIPMENT FOR AN EXTRA FEE:

- unlimited substructure extension

- plank, log scraper

- electric sawdust storage tank

- additional hydraulic tools

- automatic barking machine

- log loading ramp feeder

TECHNICAL DATA OF THE LOG TO BE WORKED:

- log diameter – 1150mm

- log diameter by turning – 1300 mm

- permissible log mass – up to 5 tonnes

- standard cutting length – 4800 mm (for the option with any length)